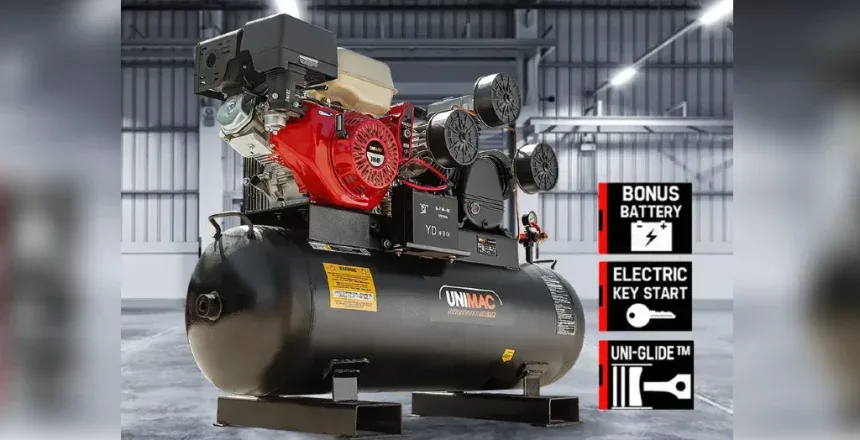

Excerpt: This hands‑on Australian guide reviews the UNIMAC 115PSI Air Compressor (150L, 18HP, electric key start) for workshops, property maintenance, and emergency support tasks. Learn how it works, where it shines, safety considerations, upkeep, and how it compares.

Last updated: 13 August 2025

Below we break down how it works, key features, advantages, limitations, realistic use cases, and how to keep it running safely and efficiently over time.

Key Features

150L Receiver

The 150‑litre tank provides a substantial air buffer, reducing compressor cycling and helping maintain steady pressure for tools with intermittent bursts.

18HP Petrol Engine

Delivers strong output for demanding pneumatic tools in areas without reliable mains power—ideal for rural and mobile setups.

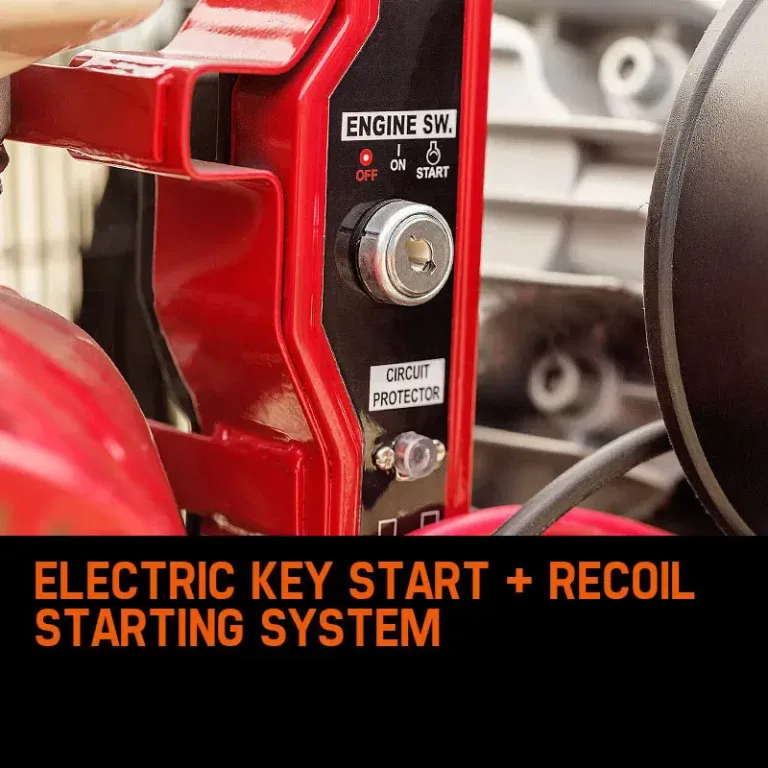

Electric Key Start

Quicker, safer starts when time matters. A manual pull‑start backup is commonly included, but key start speeds deployment and reduces fatigue.

Up to 115 PSI (≈ 790 kPa)

Suitable for most workshop and property maintenance tasks. Always check tool CFM/LPM requirements and pressure ratings before use.

Twin Outlet & Regulation

Typical configurations provide gauges, regulator, and outlets to run multiple tools or set precise working pressures.

Mobility‑Ready Frame

Heavy but relocatable with appropriate trolley, skid, or vehicle mounting. Consider vibration isolators for ute trays.

How It Works

A petrol engine turns the compressor pump via a belt drive, drawing in atmospheric air and compressing it into the receiver. A pressure switch stops the engine at the cut‑out (around 115 PSI) and restarts at cut‑in. Moisture condenses in the tank and lines, so a drain and appropriate filtration are essential.

Air tools each have a flow requirement measured in CFM or LPM at a set pressure. The UNIMAC’s combination of 18HP power and 150L capacity helps maintain those flows during sustained use, though you should avoid exceeding the manufacturer duty cycle. For spray applications or sensitive equipment, add dryers/filters and use appropriate hose diameters to minimise pressure drop.

“`

For emergency readiness, store the unit with fuel stabiliser, keep the battery charged for the key start, and run it periodically under load. Place it outdoors or in a well‑ventilated area: petrol engines produce carbon monoxide and must never operate in enclosed spaces.

Benefits & Advantages of the UNIMAC 115PSI Air Compressor

Power and independence: Petrol power means you can deploy full‑size pneumatic tools without relying on grid power—ideal on rural blocks, construction sites, or during outages.

Rapid readiness: Electric key start speeds deployment, reducing downtime during critical maintenance windows.

High throughput: The 150L tank and 18HP engine support tools like 1/2″ impact wrenches, blow guns, staplers, and some paint prep tasks when paired with the right filtration.

Mount to a ute tray or skid for mobile work—consider tie‑downs and isolation mounts.

From inflating tractor tyres to powering nailers, impact guns, and cleaning with air blow‑off.

Common consumables (belts, filters, oil) are straightforward to source and replace.

Limitations & Safety Considerations

- Noise & fumes: Operate outdoors or in well‑ventilated areas. Use hearing protection and never run petrol equipment indoors.

- Moisture: Drain the receiver daily in humid conditions. Add water traps/dryers for painting and sensitive tools.

- Weight & handling: This is a heavy unit—use proper lifting equipment and secure transport.

- Duty cycle: Respect the recommended duty cycle; continuous overrun can reduce pump life.

- Pressure equipment compliance: Air receivers require periodic inspection. Follow Australian standards and local regulations.

- Fire safety: Keep fuel away from ignition sources; store safely and cool the engine before refuelling.

User Scenarios (Fire Service & Public)

1) Rural Brigade Support

A volunteer brigade stores the compressor in a shed to maintain UHF mounting hardware, inflate off‑road tyres after rough tracks, and run an impact wrench for quick vehicle repairs during busy fire season.

2) Property Maintenance

A small farm uses it to power nailers for fencing and to clean seeders with blow‑off air. The key start saves time when weather windows are short.

3) Mobile Mechanic

A ute‑mounted setup supports tyre services and rattle‑gun work on remote jobs, paired with a moisture trap and 3/8″ hoses to keep pressure drop low.

Maintenance & Care Guide

A petrol compressor lasts when treated like any critical engine‑driven asset. Follow the schedule in the manual, and keep a simple logbook.

Daily / Pre‑Use

- Check oil level (engine & pump) and fuel.

- Inspect belts, guards, and hoses for damage.

- Drain the receiver after use; crack the valve slowly.

- Confirm gauges, regulator, and safety valve function.

Periodic

- Change engine oil as specified; replace filters.

- Grease/align belts; replace when cracked or glazed.

- Inspect receiver for corrosion; check compliance tags.

- Test battery and clean terminals for key‑start reliability.

Comparison Snapshot

| Model | Tank | Drive / Power | Typical Use | Pros | Cons |

|---|---|---|---|---|---|

| UNIMAC 115PSI Air Compressor (this review) | 150L | Petrol, ~18HP, key start | Remote work, large tools, rapid deployment | Portable power, high throughput, off‑grid | Noise, fumes, heavier handling |

| UNIMAC 50L 3HP Electric (ACM‑500) | 50L | 240V electric, ~3HP | Light workshop, DIY, limited duty | Quieter, no fumes, easier to store | Lower flow, requires mains power |

| 100–150L Petrol Class (Generic) | 100–150L | Petrol 10–18HP | Mobile trade & farm | Good mobility & output | Weight; requires ventilation |

FAQs

Can it run a 1/2″ impact wrench continuously?

It’s well‑suited for frequent bursts. For continuous heavy use, confirm CFM/LPM against tool specs and respect duty cycle to avoid overheating.

Is 115 PSI enough for spray painting?

Pressure is adequate; flow and air quality are the bigger factors. Use appropriate filtration/drying and check gun CFM at working pressure.

Can I store it inside a shed?

Yes, but operate it outside or with strong ventilation due to exhaust. Keep clearances around the engine and use CO‑safe practices.

What hoses should I use?

Use quality 3/8″ or larger hoses for high‑flow tools to reduce pressure drop. Shorter runs and high‑flow couplers help performance.

How often should I drain the tank?

After each use in humid climates and at least daily during regular use. Moisture causes corrosion and affects air quality.

Does it charge the battery while running?

Most petrol units include a charging system, but maintain the battery with a smart charger when stored to ensure reliable key starts.

Is it suitable for emergency services?

Yes—as a support tool for vehicle and equipment maintenance, tyre inflation, and general workshop tasks. It’s not a firefighting pump.

What fuel should I use?

Use fresh unleaded as specified and add a stabiliser for storage. Store fuel in approved containers away from ignition sources.

Where to Buy in Australia

Links & Manuals

- Manufacturer page / specs: UNIMAC 115PSI Air Compressor 150L 18HP Electric Key Start

- Safe Work Australia – Compressed Air Guidance: safeworkaustralia.gov.au

- Standards (e.g., AS/NZS 3788 In‑service inspection; AS 4343 Hazard levels): standards.org.au

Police · Fire · Ambulance

SES (Flood/Storm)

Poisons Information

- Log hours; change engine oil on schedule.

- Drain receiver after each session; inspect for rust.

- Keep spare belt, air filter, and plug on hand.

- Use fuel stabiliser for seasonal storage; run monthly.

- Fit water trap and regulator matched to your tools.

For brigade workshops and mobile trade setups, standardise hose couplers across vehicles, keep a calibrated pressure gauge in each kit, and schedule AS/NZS‑aligned inspections for the receiver. Consider an enclosure or baffle for noise management, ensuring ventilation meets the engine’s air and cooling needs.

Credits & Review Notes

This practical review draws on common specifications for the UNIMAC 115PSI Air Compressor class and field practices for safe compressed‑air use in Australia. Always verify the latest manual and local compliance requirements for your site.